This is a reconstruction of paper from Oscar 2004. He

used @Risk software to carry out the risk assessment. I am reconstructing his paper

using R- software taking the same model input values. So for

details, please refer to the paper of Oscar 2004. The following are the important model parameters described in that paper.

Model design

The

following 5 nodes were considered during model development.

Node 1- Retail

"The

incidence of Salmonella contamination of whole chickens ranged from 0% to 100%

with a median value of 30%. The MPN of Salmonella on contaminated whole

chickens is low, often below 10 MPN, whereas the maximum MPN per chicken ranges

from >300 to >1100. A minimum value of 1 MPN (by definition, the minimum

level of contamination that is possible), a median value of 10 MPN, and a

maximum value of 450 MPN per chicken were used to define the input settings for

the PERT distribution for the extent of Salmonella contamination of

ready-to-cook whole chickens at retail."

Node 2- Consumer Transport

Node 2- Consumer Transport

"Time

and temperature data of fresh meat showed that the time of consumer transport

ranged from 0.2 to 6.3 h with a median time of 1 h. The temperature of fresh

meat when it arrived in the consumer’s home ranged from minus 3.9 to 21.1 oC

with a median temperature of 7.8 oC. These values were used to

define the input settings for the PERT distributions for time and temperature

in the growth model, which was then simulated. A predicted incidence of

potential growth events during consumer transport of 0.02% was obtained and was

used to define the incidence of growth events for this node.

The growth model showed

that the extent of potential growth events would range from 0.0005 to 0.15 log cycles

with a median value of 0.04 log cycles. These values were used to define the

input settings for the PERT distribution for the extent of potential Salmonella

growth during consumer transport."

Node 3- Cooking

"A PERT

distribution was used to model the variability and uncertainty of final cooked

temperature, which was reported to range from 26 to 93 oC with a

mean of 62 oC. However, PERT settings of 55, 62 and 70 oC

were used because the thermal inactivation model only had a temperature range

of 55 to 70 oC. It was assumed that chickens were cooked in a home oven and that Salmonella were exposed to the final cooked

temperature for a minimum of 15 min, a median of 30 min, and a maximum of 45

min.

Results of the

cooking model simulation indicated that the log cycle reduction of Salmonella ranged

from minus 96 to minus 0.83 with a median value of minus 8.1; these values were

used to define the PERT distribution for cooking."

Node 4- Serving

"The

incidence of food handling mistakes that could lead to cross-contamination averaged

28% among three consumer surveys and was the value used to define the incidence

of cross-contamination events for this node. The average values among studies

of 0.021, 0.057 and 0.24 for the minimum, median and maximum transfer rates,

respectively, of Salmonella were used to define the PERT distribution for cross-contamination during serving."

Node 5- Consumption

"Based

on these data, the input settings for the PERT distribution for illness dose were

a minimum of 1 log MPN, a median of 3 log MPN and a maximum of 7 log MPN. Dose

response was modeled as a discrete event. For an illness to occur from

consumption of a cooked chicken, the dose of Salmonella consumed had to exceed

the illness dose that was randomly assigned to that chicken or iteration by the

model. Thus, the outcome of the dose response was discrete: no illness or

illness."

Model simulation

The model was simulated with R-software using mc2d

package with 100001 numbers of iteration. The code has not been provided in

this page, to keep it simple.

Model Output:

The

output from the model in R-software is given below.

> summary(Risk)

Retail_log_contamination_Input1

:

mean

sd Min 2.5%

25% 50% 75% 97.5%

Max nsv Na's

NoUnc 1.12 0.503 0.00632 0.251

0.732 1.09 1.48 2.13 2.64 1e+05 0

Retail_MPN_Number_output1 :

mean

sd Min 2.5% 25% 50% 75% 97.5% Max

nsv Na's

NoUnc 7.75 23.1 0

0 0 0 4 73 412 1e+05 0

Transport_log_Growth_Input2 :

mean

sd Min 2.5%

25% 50% 75% 97.5%

Max nsv Na's

NoUnc 0.0518 0.0269 0.00067

0.00897 0.031 0.0491 0.07 0.109 0.145 1e+05

0

Transport_MPN_Number_output2 :

mean

sd Min 2.5% 25% 50% 75% 97.5% Max

nsv Na's

NoUnc 7.75 23.1 0

0 0 0 4 73 412 1e+05 0

Cooking_log_destruction_Input3

:

mean sd Min

2.5% 25% 50%

75% 97.5% Max nsv Na's

NoUnc -21.6 14.9 -90.6 -56.9

-30.4 -18.5 -9.74 -2.14 -0.831 1e+05 0

Cooking_MPN_Number_output3 :

mean

sd Min 2.5% 25% 50% 75% 97.5% Max

nsv Na's

NoUnc 0.00735 0.211 0

0 0 0

0 0 22 1e+05

0

Serving_rate_Crosscontamination_Input4

:

mean

sd Min 2.5%

25% 50% 75% 97.5%

Max nsv Na's

NoUnc 0.0817 0.0371 0.0211

0.0277 0.0522 0.076 0.106 0.165 0.225 1e+05

0

Serving_MPN_Number_output4 :

mean

sd Min 2.5% 25% 50% 75% 97.5% Max

nsv Na's

NoUnc 0.178 1.18 0

0 0 0 0 2

58 1e+05 0

Consumption_log_illness_dose_Input5

:

mean

sd Min 2.5% 25%

50% 75% 97.5% Max

nsv Na's

NoUnc 3.33 1.11 1.02 1.48 2.48

3.25 4.12 5.6 6.88 1e+05 0

Consumption_risk_illness_output5

:

mean sd Min 2.5% 25% 50% 75% 97.5%

Max nsv Na's

NoUnc 0.000724 0.0122 0

0 0 0 0

0.0018 1.31 1e+05 0

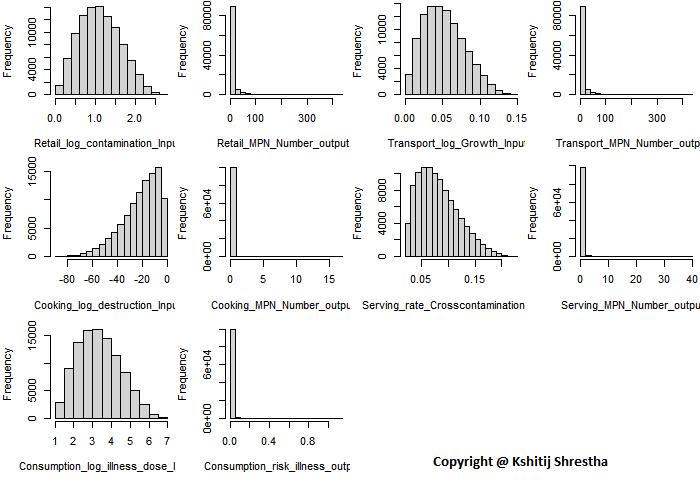

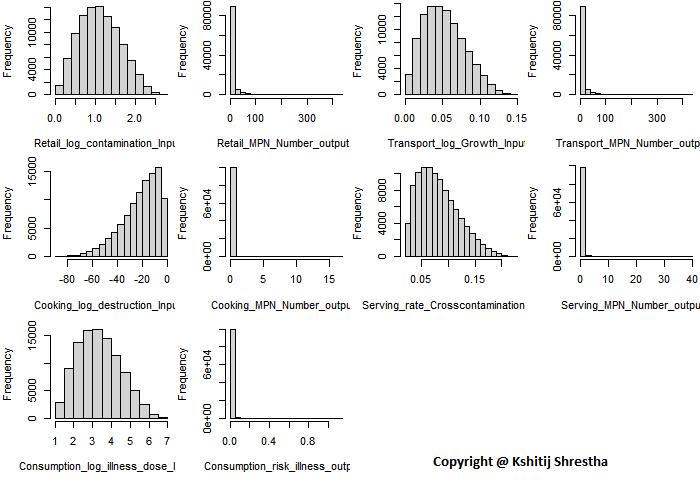

Graphical Output:

The graphical output is shown below.

Results:

I am not going to discuss all the

results and the graph. You can refer to the original paper of Oscar 2004 for

details. If you have questions, please put them in comment.

The assumptions about the model input

made on this simulation were based on the good manufacturing practices. If that

GMP is respected, we should expect to have low risk from salmonella.

Based on this

simulation, the risk of illness was found to be around 2 cases per 100000 chickens. This can

be considered relatively a low risk. Hence, we can conclude that if all the GMP

conditions are respected within the variability described in the model, the

risk of salmonella from chicken consumed after proper cooking and serving is

relatively low.

Please provide your comments and

feedback.

No comments:

Post a Comment